| Sign In | Join Free | My fazendomedia.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My fazendomedia.com |

|

Brand Name : HGalloytool

Model Number : D9*100 H7

Certification : ISO9001: 2008

Place of Origin : Hunan,China (Mainland)

MOQ : Negotiation

Price : Negotiation

Payment Terms : L/C, T/T, Western Union

Supply Ability : 20 Tons per month

Delivery Time : 20-30 days after order confirmed

Packaging Details : Plastic boxes inside and cartons outside

Application : End mills,drills,cutting tools

Material : 100% virgin tungsten carbide

Surface : Polished and Blank

Performance : Wear Resistance

Shape : Cylinder carbide

Advantage : HIP Sintering,long lifespan

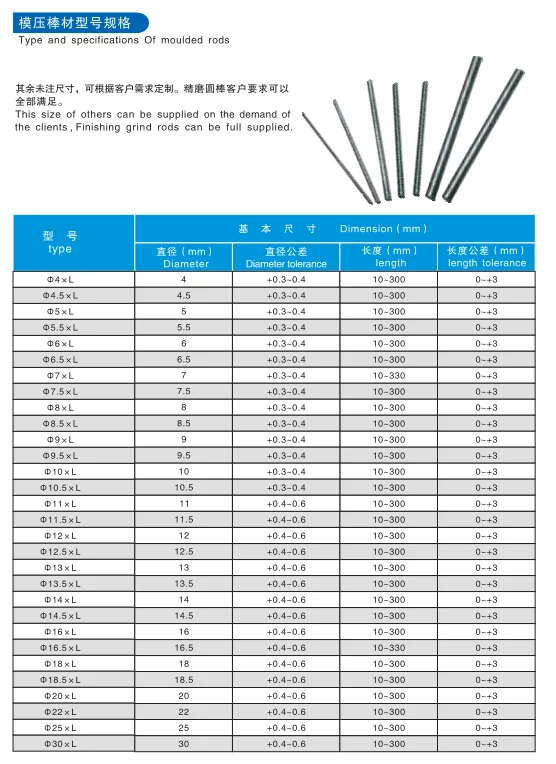

High Quality Custom Various Typescircular Polishing rod Hard alloy cemented tungsten carbide round bar

Product Description

1. Extruded rod and HIP sintering.

2. Ultrafine particle size powder.

3. Runout and roundness can be less than 5 microns (0.005mm).

4. Carbide rods are solid or with straight / spiral coolant holes.

5.100% virgin material

6.Various sizes and full types stock available

7.Products can be customized upon requirement

Features

As for tungsten carbide rod, below are the general features for your reference

For more details of specific type, please inform us:

1.Better wear resistance, higher toughness, better deformation and fracture resistance, results in a long life and good size accuracy

2.Adopt advanced automatic extrusion equipment

3.HIP sintering and precision grinding to ensure the good performance

4.Both blank and finished tungsten carbide rods available

5.Can reach a mirror effect surface after accurate grinding and polishing

Grade and Application

|

Grade |

Hardness |

TRS |

Density |

Recommended Applications |

|

YG6X |

92 |

1800 |

14.9 |

It can be used for the steel wire, non-ferrous metal wire or rod die under the condition of less stress. |

|

YG6 |

90.5 |

2000 |

14.9 |

It can be used for steel wire, non-ferrous metal and alloy bars under 20mm diameter with greater stress condition, and can also be used to pull tubing with a diameter of less than 10mm. |

|

YG8 |

90 |

2200 |

14.7 |

It can be use in steel, non-ferrous metal and alloy bars and pipes, and also for manufacturing machinery parts, tools and vulnerable parts. |

|

YG8.2 |

89 |

2000 |

14.6 | |

|

YG8L |

89 |

2000 |

14.6 | |

|

YG11 |

88.5 |

2600 |

14.4 |

It can be used for high compression steel rod and steel tube drawing, working top hammer, perforation and stamping die under greater stress. |

|

YG15 |

87 |

2600 |

14 | |

|

YL50 |

87 |

2600 |

14.4 | |

|

YG20 |

85 |

2800 |

13.6 |

It can be used to make punching film tools, such as punching watch parts, stamping battery shell, tooth paste mould, small size steel ball, screw, nut, etc. |

|

YG20C |

83.5 |

2800 |

13.6 |

It can be used for cold forging, cold pressing, cold pressing mould in standard parts, bearing, tool industries, etc., and is also useful in warhead and shell staming die. |

|

TL40.5 |

82 |

2800 |

13.3 | |

|

YB50 |

90.5 |

2600 |

14 |

It has high hardness and strength, excellent wear resistance, which can be used in the production of IC wireframe, plastic sealing film, drawing die, nozzle, ultra-thin blade, etc. |

|

YB20 |

92 |

2200 |

14.5 |

It has high hardness, high strength and superior wear-resisting property, which is suitable for low, medium-speed electronic class progressive die and punch and for copper and aluminum thin sheet stamping. |

Quality Control

1.All raw materials are tested in terms of density, hardness and TRS, each rod will be drop from 1.2m higher place

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

FAQ

| Q1: Are you a factory or a trading company? |

| A: We are a factory. We have been focusing on Tungsten Carbide for over 30 years. |

| Q2:What is your principle for the samples? |

| A: We offer free samples if you are willing to pay the freight. |

| Q3:What is your delivery time? |

| A: Generally it is 5 to 7 days if your required goods are in stock, otherwise it takes 20 to 30 days when there is no stock. |

| Q4:Do you have any test reports or certificates? |

| A: Yes, we can offer certificate of ISO9000:2008, we also report our test results for your reference. |

| Q5: Do you provide after-sale service? |

| A: Yes. So if you find any problem after using our cutting tools, please do not hesitate to tell us, we’ll help you to solve it as soon as possible. Your any feedback to products is our way to improvement. |

Reference Drawing

Product photo

|

|

Custom Various Cemented Tungsten Carbide Bar / Hard Alloy Typescircular Polishing Rod Images |